Af – Austenite Finish – The temperature at which the Martensite to Austenite transformation is completed in a single stage transformation.

As – Austenite Start – The temperature at which the Martensite to Austenite transformation begins on heating in a single stage transformation.

Austenite – The high temperature phase of Nickel Titanium. In its austenitic phase, NiTi is stiff and elastic and will immediately return to shape after bending.

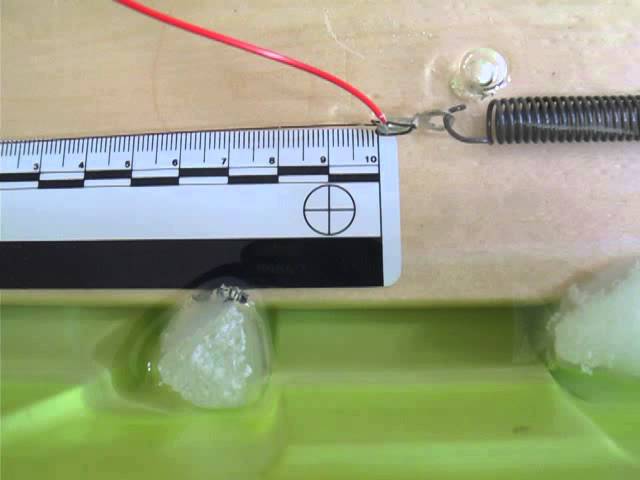

Hysteresis – The difference in bending loads during loading and unloading.

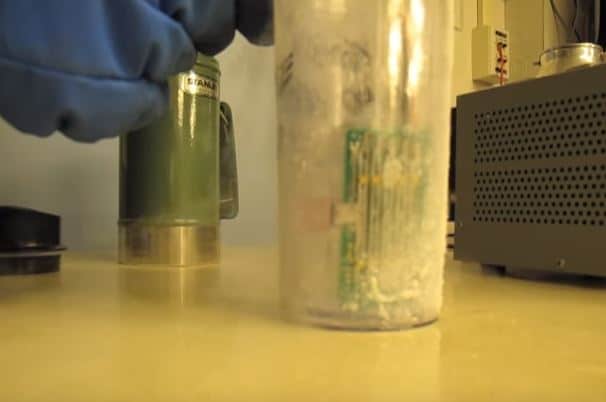

Martensite – The low temperature phase of Nickel Titanium. In its martensitic phase, Niti is soft and bends easily. NiTi will stay in this state until exposed to heat above its TTR. NiTi in its martensitic state is responsive to chilling, as it becomes even softer and more easily bent.

Mf – Martensitic Finish – The temperature at which the transformation from Austenite to Martensite is completed on cooling a single stage transformation.

Ms – Martensite Start – The temperature at which the transformation from Austenite to Martensite begins on cooling in a single stage transformation.

Shape Memory – An apparent plastic deformation in the martensitic phase, which undergoes a thermo-elastic change in the crystal structure when heated through its transformation temperature range, resulting in a recovery of the deformation.

Superelasticity – A nonlinear recoverable deformation behavior of Nickel Titanium shape memory alloys at temperatures above Af. The nonlinear deformation arises from the stress-induced formation of martensite on loading and the spontaneous reversion of this crystal structure to austenite upon unloading.